Rubber Shoe Sole Injection Molding Machine

- group name

- Single color rubber injection for shoe sole

- Min Order

- 1 set

- brand name

- Lary

- model

- LRS165

- Nearest port for product export

- Ningbo, Shanghai

- Delivery clauses under the trade mode

- FOB

- Acceptable payment methods

- T/T, L/C, PayPal

- update time

- Sat, 07 Mar 2026 14:50:00 GMT

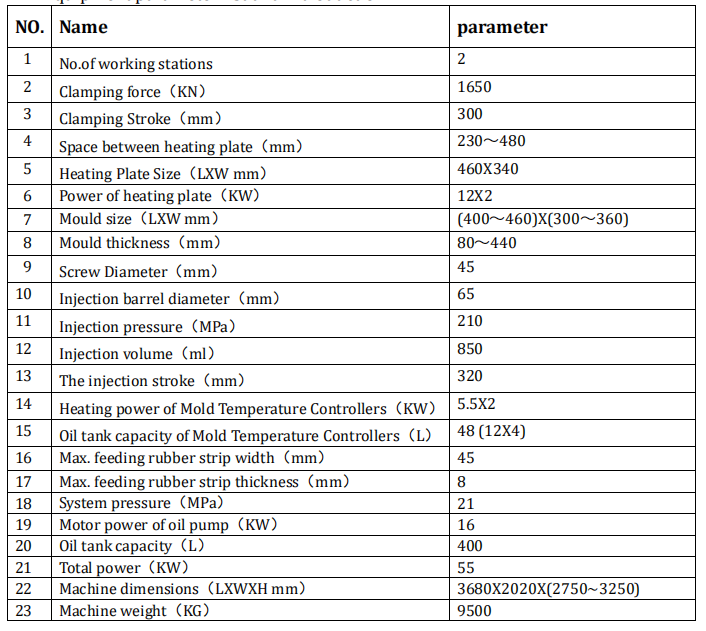

Paramtents

Condition New

Place of Origin Zhejiang, China (Mainland)

Oil tank capacity 400 L

Max Injection Volume 850 ml

Heating Plate Dimension 460X340 mm

System pressure 21 Mpa

Total Power 55 kw

Dimension (L×W×H) 3680X2020X(2750~3250)) mm

Weight 9.5 Ton

Engineers Portugal team

Packging & Delivery

-

Min Order1 set

Briefing

Automatic exhaust

And automatic weighing, injecting rubber into mold cavity, etc.

Detailed

Rubber sole injection molding machine orginal from Europe

Keywords:

Rubber sole injection molding machine price

Rubber sole injection molding machine factory

Automatic rubber sole injection molding machine

Rubber sole injection molding machine for safety shoe sole

Rubber sole injection molding machine for sports shoe

Rubber shoe sole molding machine with European engineering

Product attributes:

Condition: New

Place of Origin: Zhejiang, China (Mainland)

Oil tank capacity: 400 L

Max Injection Volume: 850 ml

Heating Plate Dimension: 460X340 mm

System pressure: 21 Mpa

Total Power: 55kw

Dimension (L×W×H): 3680X2020X(2750~3250)mm

Weight: 9.5 Ton

Certification: CE

Factory or not: Factory

Engineers: Portugal team

Technical Parameters:

1. European most advanced technology, specialized in the Rubber Shoe Sole Injection Molding technology. with Compact construction, Fully automated production.

2. Only need to put the rubber strip into the feeder, you can achieve automatic metering, preheating, injecting, and automatically moving out and opening mold. Full automated production process greatly improved production efficiency, reducing labor intensity, and protecting the mold.

3. Each Worker can easily operate 4-8 stations(2-4 machines), and each station can produce 20-35Pair of Shoe Soles per hour.

4. The process of injection after clamping, greatly reducing the product flash and trimming costs. The product is more compact, improve the intrinsic quality of the product.

5. With humanized interface, you can set the Curing Time, InjectionVolume, Preheating Temperature, Curing temperature, Exhausting Parameters. And the Fault Diagnosis system can guide the maintenance staff to solve the problem in the shortest time.

6. Equipped with automatic Mold Change system. A mold can be replaced within five minutes.

7. Advanced energy-saving hydraulic control system can support 24hours’ continuous operation, with quickly response energy efficiency.

8. For Insert Color Process, single color injection machine will solve the rubber mixing problem easily, greatly improved the yield of the embedded color products, quality, and reduce costs of artificial re-treatment.

9. Optional Vacuum System, completely solve the problem of products with air.

10. Two kinds of heating systems are available, electrical heating and oil heating.

Company:

Ningbo Lary Industry Technology Co., Ltd is a joint venture with Portugal TECNIROLO Engenharia Industrial S.A. Lary is an engineering & manufacturing enterprise which inherits the concept of providing customers with best services in Europe for more than twenty years. Lary has committed to product promotion and service of shoe industry technology with Portugal TECNIROLO. Now, Lary’s current products include: rubber shoe sole injection mold machine, high precision & speed rubber injection machine, 3D scanner for shoe last, 3D shoe design software and 3D printer.

TecniRolo - Portugal and Lary Industry - China are a group of companies that work as a global solution provider for an international network over of 16 countries.

Certification:

Customers & exhibitions:

Payments and Delivering:

Payments: 40% deposit by T/T after confirming the drawings and 60% balance by T/T before delivery.

Delivering: 90 -120 days after we confirmed both side.

Contact us

Amy Ren

Ningbo Lary Industry Technology Co., Ltd.

Ningbo

Add: No.9 East of Jingu middle Road, Yinzhou District, Ningbo City, China

Web: www.larytec.com ..........com

Tel: 0086-754-88033926

Fax: 0086-754-88137126

Mob: 0086-13958255267

Email: amy..........com inlary..........com

Welcome to visit us!